Plastic Moulding Industry

GF Gasparini Federico s.r.l.

Via Brescia, 291 - 25075 Nave (Brescia) - Tel. 030 2534485

Email: [email protected]

Over 50 years of experience in the plastic moulding industry

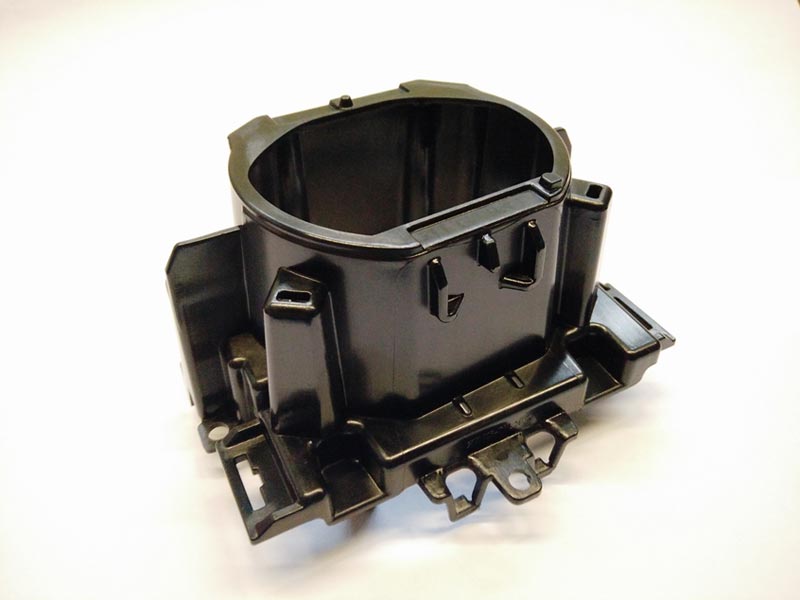

Gasparini Federico SRL has been operating for over 50 years in the field of plastics and techno-polymers injection moulding for third parties. The valuable industry experience acquired, the specialisation in the production of techno-polymer products (such as PC, PA66 and PEEK) and high flexibility allow us to offer tailor-made solutions to customers across a vast range of industrial sectors: from automotive to healthcare, from household appliance to the heating sector etc.

Plastic Moulding

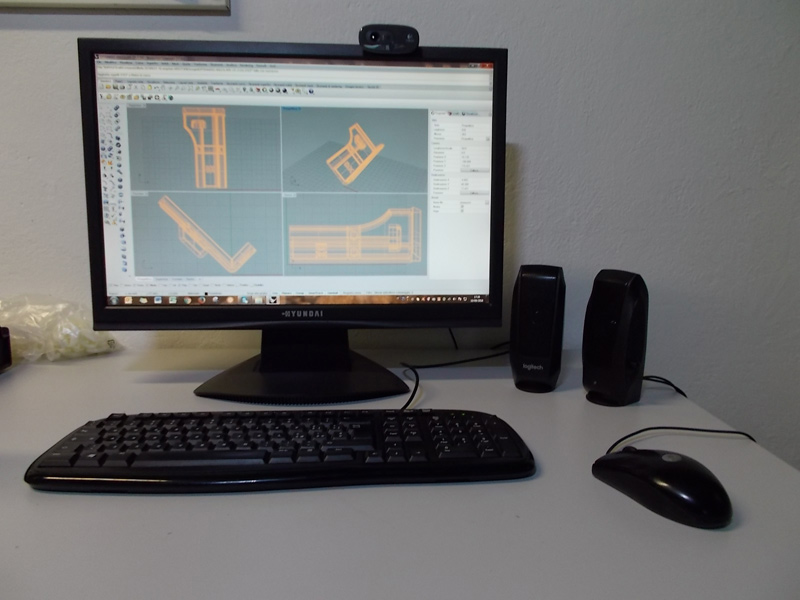

The close collaboration with mould manufacturing companies, the completely updated machinery and attention to environmental issues (2 full electric presses), the high degree of process automation and the know-how acquired allow us to follow and satisfy the Customer's needs during all the various steps: design, improvements, creation of moulds, samples, pre-series, production and shipping.

We are people who work and share goals and values day after day. The quality and reliability of the targets reached stem from the mindset of continuous improvement and the desire to work in a synergistic way. We want to improve by listening to customers, their expectations and their ideas. Being close to the customer, cutting costs, and creating ideas in the best way: these are our goals!

GF is a modern plastic moulding company.

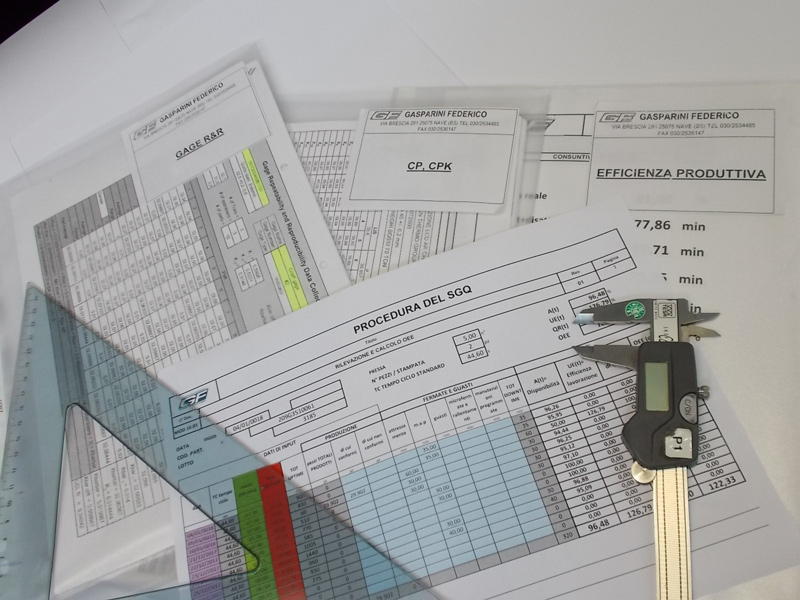

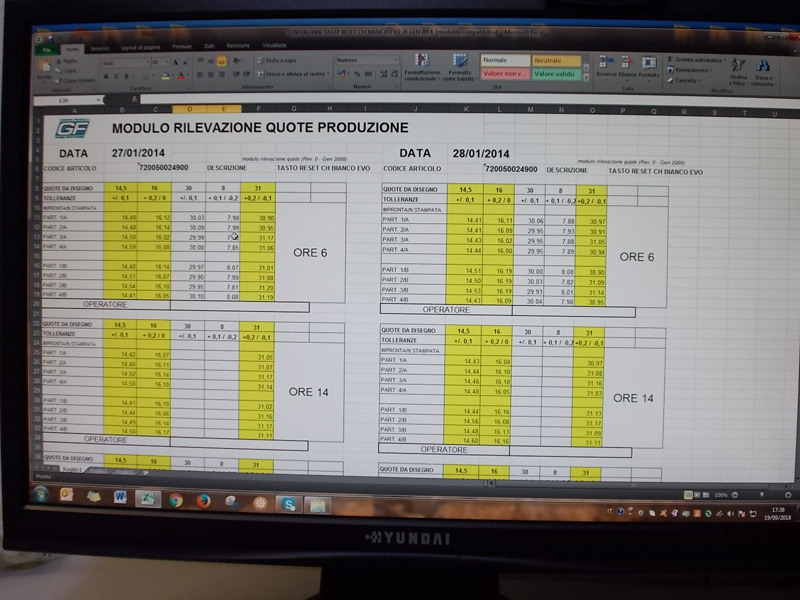

Quality Control System

For us, having a quality control system means first of all having a culture of quality and, therefore, ensuring that everyone who works for the company is involved in updating and continuously improving their skills.

This allows us to keep all phases of the company production process

under control.

We have adopted a set of procedures based on those

from ISO/TS 16949 and these procedures are constantly applied.

We have been audited by the company Intertek, which has been able to verify on behalf of one of our customers (a major national company) that we are 100% qualified to meet the standards required for supplies.

Now that we have strengthened our quality control system procedures, the next step will be to achieve ISO 9001/2015 certification.

MENU - CONTACT - DISCLAIMER